Wieland Metal Services Germany GmbH | Kornwestheim

- Finished parts according to drawing

- Quality management according to DIN EN ISO 9001:2015

- Worldwide recognized with our brand name Elmedur

Organization

70806 Kornwestheim

Germany (UTC+1)

7:00 am - 12:00 pm

12:45 pm - 4:30 pm

Friday

7:00 am - 2:30 pm

7:00 am - 12:00 pm

12:45 am - 3:00 pm

Friday

by arrangement

Facts

employees

% owned by Wieland-Werke AG

MK quotation

Products

Our products at a glance

Product categories

Headline

Back to product overviewFinished parts

Mold Manufacturing

Rods

Sectional rod

Forging Stock

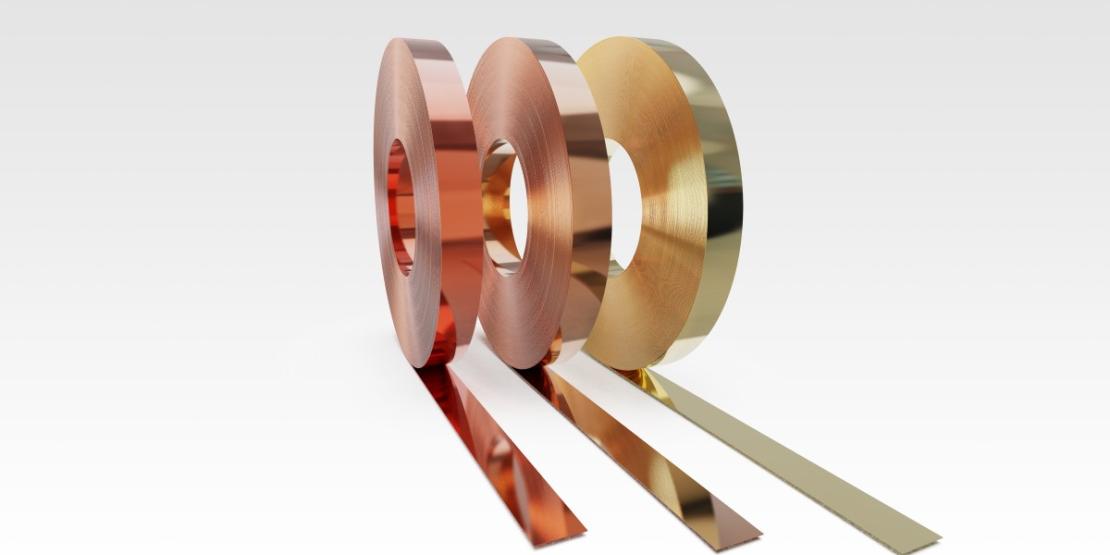

Strip

Sheets and Plates

Tubes

Wire

Do you need finished parts according to drawings? Here, too, we are your competent supplier.

We offer you for example:

- electrodes and other accessories for resistance welding technology

- input material for die-cast pistons and finished pistons

- semi-finished products made of highly conductive copper-based materials for tool and mould construction

- parts made of refractory metals

Components from Elmedur

Our Elmedur materials are particularly versatile. We produce parts from them according to drawings - and of course also individual parts. All according to your wishes and requirements.

Electrodes

No matter which electrodes you need: Among our large selection of standard electrodes you will find the right one for your purposes. We manufacture electrodes from hardenable copper materials, which are very hard and at the same time highly conductive. They are ideal for applications in which high electrical currents are transmitted under high mechanical loads.

Components made of high-melting metals

From our refractory metals molybdenum, TZM, tungsten and tantalum we manufacture parts according to drawings as well as individual parts. As the metals are very easy to process, they are ideal for a wide range of applications.

| Wieland | EN Designation | EN-No. | ASTM-UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr | ~CW111C | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Elmedur Z | CuZr | CW120C | C15000 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

Wieland hot stamping rods

Good forging results can be obtained only when all links in the process chain have been matched to each other to the optimal effect. With Wieland hot stamping rods you are offered a forging stock which comprehensively fulfils these requirements. Your benefits: uniform dark surface for reproducible processing properties, tight diameter tolerances in the drawn size range, and hence precise configuration of the slug weight.

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

Learn more

Strips for connector

Hot dip tinned copper and copper-alloy strip

Strip for semiconductor packages

Materials

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur B2 | CuBe2 | CW101C | C17200 |

| Elmedur HA | CuCoNiBe | CW103C | ~C17500 |

| Elmedur HC | CuNi2Be | CW110C | C17510 |

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| High Density (HD) | - | - | - |

| Molybdän (Mo) | - | - | - |

| Molybdän-Lanthan (ML) | - | - | - |

| Niob (Nb) | - | - | - |

| Rhenium (Re) | - | - | - |

| Tantal (Ta) | - | - | - |

| Titan (Ti) | - | - | - |

| Titan-Zirkon-Molybdän (TZM) | - | - | - |

| Wolfram (W) | - | - | - |

| Wolfram-Kupfer (TUCO) | - | - | - |

| Wolfram-Rhenium | - | - | - |

| Zirkonium (Zr) | - | - | - |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur NCS | CuNi2SiCr* | ~CW111C* | C18000 |

| Elmedur X | CuCrZr | CW106C | C18150 |

| Wieland | EN Designation | EN No. | ASTM UNS-No. |

|---|---|---|---|

| Elmedur X | CuCrZr | CW106C | C18150 |

Contact person

Get in touch - Your contact person at Wieland Metal Services Germany GmbH | Kornwestheim

![]() Christoph Altrichter

Christoph Altrichter

Managing Director

Wieland Metal Services Germany GmbH

+49 7154 8255 21

Send email

![]() Markus Hölscher

Markus Hölscher

Technics

Wieland Metal Services Germany GmbH | Kornwestheim

+49 7154 8255 16

Send email

![]() Christian Butz

Christian Butz

Casting

Wieland Metal Services Germany GmbH | Kornwestheim

+49 7154 8255 33

Send email

![]() Björn Günther

Björn Günther

Trading

Wieland Metal Services Germany GmbH | Kornwestheim

+49 7154 8255 17

Send email

![]() Zeljko Peric

Zeljko Peric

Refractory

Wieland Metal Services Germany GmbH | Kornwestheim

+49 7154 8255 19

Send email

Martin Südfeld

Martin Südfeld

Sales area west

Wieland Metal Services Germany GmbH | Kornwestheim

+49 152 3103 5114

Send email

Markus Meyer

Markus Meyer

Sales area south

Wieland Metal Services Germany GmbH | Kornwestheim

+49 7154 8255 90

Send email

Thomas Funke

Thomas Funke

Sales area east

Wieland Metal Services Germany GmbH | Kornwestheim

+49 152 22825702

Send email

Inna Jurk

Inna Jurk

Inside Sales Welding

+49-71 54 82 55-35

Send email

Wieland Metal Services Germany GmbH

Graf-Arco-Straße 36

89079 Ulm

Germany

Managing Director:

Christoph Altrichter

Court of Registration: Ulm HRB 745718

VAT Identification Number: DE358435645

Career

Start your career at Wieland Metal Services Germany GmbH | Kornwestheim

Unleash potential.

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.